Compared to the V1, the PLEX KNOCK MONITOR V2 has an improved signal-to-noise ratio (S/N) by 20dB which raises the audio clarity sufficiently and reduces the total noise 10 fold. After the right filter is applied one can clearly hear the knock spikes and determine …..

PLEX KNOCK MONITOR V2 SINGLE CHANNEL

OFTEN QUOTED AS THE “ULTIMATE KNOCK DETECTION DEVICE”, THE PLEX KNOCK MONITOR V2 HAS BEEN ESTABLISHED AS THE PREFERRED CHOICE OF PROFESSIONAL TUNERS AND ENGINE BUILDERS ALIKE.

AVAILABLE IN SINGLE AND DUAL CHANNEL WITH OPTIONAL CANBUS PORT

To use this element install or activate XStore Core plugin

SKU: Code: SYV-PKM1Often quoted as the “ultimate knock detection device”, the PLEX KNOCK MONITOR V2 has been established as the preferred choice of professional tuners and engine builders alike.

With best-in-class audio quality, an embedded 2.3” trasflective LCD display and advanced audio filtering, it delivers reliable audio and visual knock detection even for the most challenging of projects as it effectively detects knock per cylinder and throughout the RPM range.

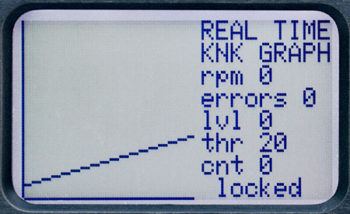

Real-time Knock Graph

Per-Cylinder Detection

Optional CAN BUS port

Advanced Audio Filtering

Built-in Freq. vs Bore Size Calculator

Super Bright LED Warning Function

Dedicated Audio DSP

Knock Threshold vs RPM Function

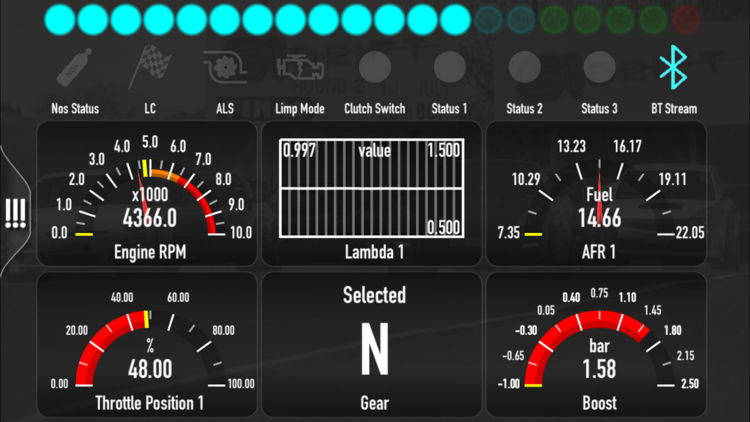

Powerful PC Analysis SW

Capture 3-dimensional knock information and log knock count with knock level per cylinder versus RPM and load or perform real-time knock detection

DEDICATED AUDIO DSP

ELECTRICAL ISOLATION

ADVANCED NOISE FILTERING

By detecting the ignition trigger of cylinder 1 and using the inputed firing order, the Knock Monitor can calculate which exact cylinder is knocking for up to 8 cylinders

Store your most common engine settings in 8 different presets and name them accordingly for easier retrieval or use the 2 pre-dermined presets for basic knock detection

A handy on-screen engine bore size reference lets you select the corresponding knock frequency filter effortlessly by simply choosing your cylinder bore size

£100.00

£100.00

Reviews

There are no reviews yet.